Mechanical characteristics ※ The three-axis adopts a high-performance sliding rail design, providing high-speed and stable cutting supply. The unique design ensures that the thermal deformation of the head is the same as that of the Y-axis and can be automatically compensated The spindle head is a heavy box structure with reinforced internal ribs and high rigidity. Using C3 grade precision roller screw combined with precision nut and tail end pre tensioning device, ensuring that the thermal deformation of the body's back gap reaches the minimum value The G-type machine adopts a heavy cutting gear type spindle head, which is a full tooth high and low two-stage variable speed transmission. The imported gears used are all made of chromium steel alloy material. Made by infiltration solution hardening treatment and JIB-0 precision grinding, to ensure the long service life and machining accuracy of the gearbox bearing gears, the spindle head adopts dual cooling inside and outside.

15989519333 (Mr Xu)

Online consultation Message consultation

Main specifications and technical parameters

| Main technical parameters |

||||

| Mechanical specifications |

name |

Specifications |

Company |

|

| trip |

X-axis travel |

1500 |

mm |

|

| Travel Y-axis |

800 |

mm |

||

| Z-axis travel |

700 |

mm |

||

| Distance from spindle nose to worktable |

170-870 |

mm |

||

| Distance from spindle center to column slide surface |

810 |

mm |

||

| workbench |

Workbench size |

1700×800 |

mm |

|

| maximum load |

1500 |

kg |

||

| T-shaped groove (number of grooves - size - spacing) |

5-22-135 |

mm |

||

| principal axis |

Spindle speed |

6000 |

rpm |

|

| Main spindle tool holder form |

BT-50 |

|||

| Spindle diameter |

Ø155 |

mm |

||

| Transmission mode |

Belt type |

|||

| Feed rate |

Fast moving speed X/Y/Z |

10 / 10/ 12 |

m/min |

|

| feed rate |

1~8000 |

mm/min |

||

| Machine accuracy |

X/Y/Z-axis positioning accuracy |

±0.005/300 |

mm |

|

| X/Y/Z axis repetition accuracy |

±0.005 |

mm |

||

| motor |

Spindle motor |

15/18.5 |

KW |

|

| X. Y and Z-axis drive motors |

3.0/3.0/3.0 |

KW |

||

| Oil pump |

DY-YBM-750 |

750W |

||

| Tool magazine |

Tool magazine capacity |

24 |

branch |

|

| Automatic tool change type |

Circular blade arm type |

|||

| Knife handle specifications |

BT-50 |

|||

| Knife handle pull nail |

45 |

degree |

||

| Maximum tool length |

300 |

mm |

||

| Maximum tool diameter |

Full of knives |

Ø110 |

mm |

|

| Neighboring empty knife |

Ø200 |

mm |

||

| Maximum tool weight |

18 |

kg |

||

| Tool change time |

2-5 |

sec |

||

| Land occupation space |

Mechanical height |

3450 |

mm |

|

| Floor space (length x width) |

4380*3500 |

mm |

||

| Mechanical weight |

11000 |

kg |

||

| Total electrical capacity |

40 |

KVA |

||

| Pressure demand |

0.5 ~ 0.8 |

MPa |

||

| Standard attachments |

|||

| name |

Specifications |

quantity |

Company |

| CNC system |

Fanuc 0i MF |

1 |

set |

| principal axis |

RD5002 |

1 |

group |

| Fully enclosed outer cover |

sheet metal |

1 |

set |

| Automatic lubrication system |

YET-B2P2 |

1 |

set |

| heat exchanger |

RC-25AR |

1 |

platform |

| Foundation cushion block |

HT250 |

1 |

set |

| hold-all |

1 |

set |

|

| Lock knife holder lock knife wrench |

BT-50 |

1 |

set |

| Knife handle (including rivets) |

BT-50 |

1 |

group |

| Cable line |

4 X 2.5mm ² X 5 meters |

1 |

strip |

| System Operation Manual |

1 |

set |

|

| Optional accessories |

|||

| name |

Specifications |

quantity |

Company |

| Circular arm type tool magazine |

BT-50-24T |

platform |

|

| Fourth axis |

AR-170R |

set |

|

| Fifth axis |

FAR125 |

set |

|

| High pressure oil pump |

platform |

||

| Oil water separator |

group |

||

Main brands of purchased accessories

| Item sequence

|

Product Name |

Specifications |

Manufacturer |

remarks |

| 1 |

CNC system |

0i-MF |

Fanuc (Japan) |

|

| 2 |

Spindle motor |

βiP30/8000(143Nm) |

Fanuc (Japan) |

|

| 3 |

X-axis motor |

ΒiS40/2000(36Nm) |

Fanuc (Japan) |

|

| 4 |

Y-axis motor |

ΒiS40/2000(36Nm) |

Fanuc (Japan) |

|

| 5 |

Z-axis motor |

ΒiS40B/2000(36Nm) |

Fanuc (Japan) |

|

| 6 |

X-axis ball screw |

Grade C3 with a diameter of 63X10 |

Shangyin/Intime (Taiwan) |

|

| 7 |

Y-axis ball screw |

Grade C3 with a diameter of 63X10 |

Shangyin/Intime (Taiwan) |

|

| 8 |

Z-axis ball screw |

Grade C3 with a diameter of 50X10 |

Shangyin/Intime (Taiwan) |

|

| 9 |

X-axis guide rail |

Hard track |

(Domestic) |

|

| 10 |

Y-axis guide rail |

Hard track |

(Domestic) |

|

| 11 |

Z-axis guide rail |

Hard track |

(Domestic) |

|

| 12 |

principal axis |

RD5002 |

Weilong (Taiwan) |

|

| 13 |

coupling |

Diameter 65 plum blossom shape |

R W (Germany) |

|

| 14 |

Microcomputer-based oiling machine |

AC220V-2L |

Proton (domestic) |

|

| 15 6 |

Air filter |

AC40 |

SMC (Japan) |

|

| 16 |

heat exchanger |

RC-25AR |

Ruike (domestic) |

|

| 17 |

transformer |

35KVA |

Hongbao (domestic) |

|

| 18 |

Oil pump |

DY-YBM-750 |

Longxin (domestic) |

|

| 19 |

Electrical components |

Mitsubishi |

(Japan) |

|

| 20 |

Spindle bearings |

Grade P4 with a diameter of 130X85X22 Grade P4 with a diameter of 125X80X22 |

Germany |

|

| 21 |

Pulse handwheel |

HC121AB |

Gu Yi (Taiwan) |

|

| 22 |

Oil cooler |

Ruike (Taiwan) |

Lubricating Oil Demand Table

Table (1)

| Lubrication position |

Spindle bearings |

X. Y and Z-axis bearings |

Oil cooler |

| Oil characteristics |

High and low temperature resistance |

High and low temperature resistance |

High heat transfer and good lubrication |

| Lubricating oil status |

grease |

grease |

Thin oil |

| Oil change interval |

Timely supplementation |

Timely supplementation |

Replace once a year |

| Fuel tank capacity |

20L |

||

| Recommended oil |

NOK KLUEBER’S ISO FLEX NBUIS NO.2 |

NOK KLUEBER’S ISO FLEX NBUIS NO.2 |

ISO VG10 MOBIL DTE OIL 21 |

Table (II)

| Lubrication position |

Sliding rail, ball screw guide |

Oil pressure device |

cutting fluid |

| Lubricating oil status |

Thin oil |

Thin oil |

Thin oil |

| Oil characteristics |

1) Viscosity ISO VG68 2) Wear resistant and pressure resistant |

1) Viscosity ISO VG32, anti foam, anti-oxidation and anti emulsification |

1) High heat transfer performance 2) Well lubricated |

| Lubrication method |

Centralized lubrication |

loop |

loop |

| Oil change interval |

Weekly supplementation |

Replace once a year |

Monthly replacement |

| Fuel tank capacity |

2L |

40L |

160L |

| Recommended oil |

1) Guoguang brand lubricating oil 68 2)MOBIL VACTRA OIL NO.2 3)ESSO FEBIS K68 4)SHELL TONNA OIL T68 5)CHEVRON WAY LUBRICANT 68

|

1) Guoguang brand hydraulic oil 32AW 2)MOBIL D.T.E OIL 13 3)ESSO NUTO H32 4)SHELL TELLUS OIL 32 5)CHEVRON EP HYDRAULIC OIL 32 |

1) Guoguang brand cutting oil 32C 2)MOBIL ESUL TRAN B4 3)ESSO PENNEX 44 OR KUTWELL30 4)SHELL DROMUS OILB OR GARIA 31 5)B.P CIRORA DIATSOL CUTROA |

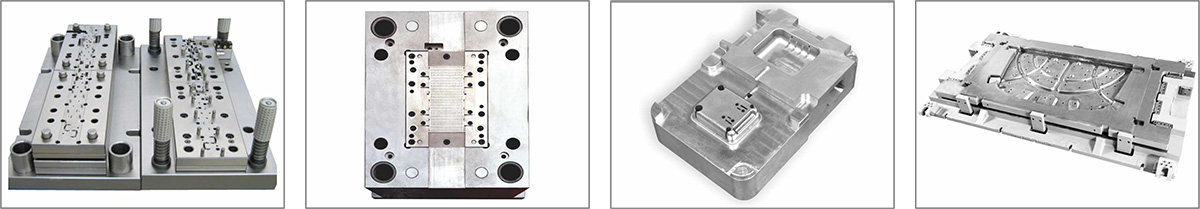

Processing applicationsProcessing application

Precision molds, parts, hardware, automotive, aviation